99-04 Heads vs. 05 Heads

This thread is to show the differences between '05 Twin Cam heads and the previous 99-04 heads. In '05 the Twin Cam heads received design changes that were already in use in Buell's and '04-present Sportsters. Both of which will rev much higher than a big twin and they both put the valves through greater stresses.

The changes include 7mm valves, valve guides, springs, top collars, bottom collars (spring cup), keepers, and valve seals. All these changes are easily noticeable just by looking at the parts side by side. But there are some other changes that don't just jump out at you. In the following posts I will point out many of the changes and what the effects could be.

Guides & Ports

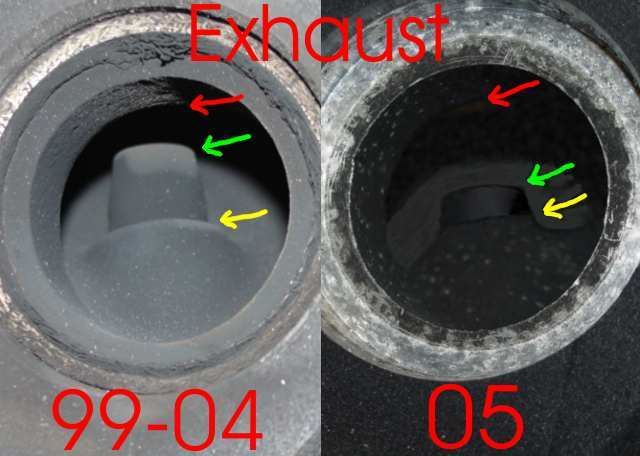

The first area to look at is the exhaust and specifically the guides. The '05 heads, used for this post, were brand new take offs and had no carbon in the exhaust port. This made taking pictures of the '05 port very difficult. You can see the used port with carbon took a much better picture (Picture 1).

When you compare the 2 exhaust ports you can see that the valve guide protrudes further into the port on the earlier heads. The valve guide height is between the yellow and green arrows (Picture 1). In the '05 heads, the valve guide doesn't block as much of the port. Compare the distance between the green and red arrows (Picture 1).

Picture 1

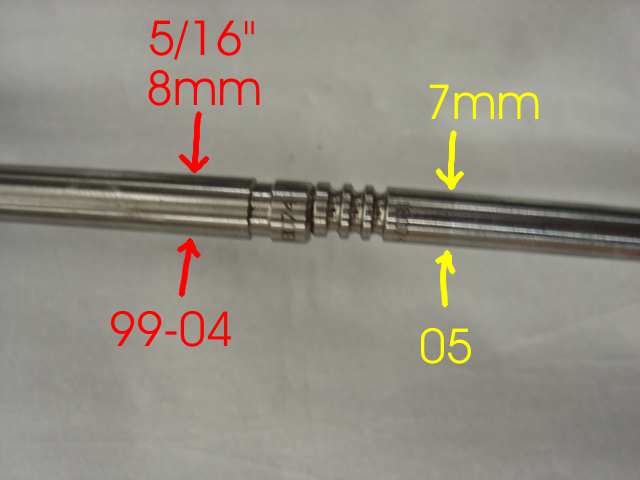

In the '05 heads the valve stem is only 7mm as compared to 5/16" (8mm) (Picture 4). So the '05 heads with the, shorter valve guides, also have thinner valve stems that block the port less than the thicker stems in the earlier heads (Picture 2,3). This means the Port has considerable less stuff in the way and actually yields a larger port volume with less obstruction. This is the case with both the intake and exhaust port comparisons shown (Picture 1,2).

The valve guides have the same OD but the ID is obviously different to accommodate the different valve stem sizes (Picture 3).

Picture 2

Picture 3

Picture 3

Picture 4

Picture 4

Valve Seals

Valve Seals

The earlier valve seals were small press on metal seals. They have a single rubber seal/wiper. The '05 seals are much larger and are attached to the bottom spring collar. It uses a thicker rubber seal with many wiping ribs. Compare the Green arrows (Picture 5), this creates the seal around the valve stem. The seal is securely held down by the spring pressure on the bottom collar when installed.

Picture 5

The yellow arrow (Picture 6) points to where the seal contacts the outside of the valve guide, creating the seal with the guide. For the seal to work properly, it must seal out oil at both the valve stem and the valve guide.

The green arrow (picture 6) shows that the old seal relies on a metal to metal contact with the guide. TIP: A little green loctite helps hold the seals on and helps them seal better to the guide. DON'T GET ANY IN THE GUIDE OR ON THE VALVE STEM.

Picture 6

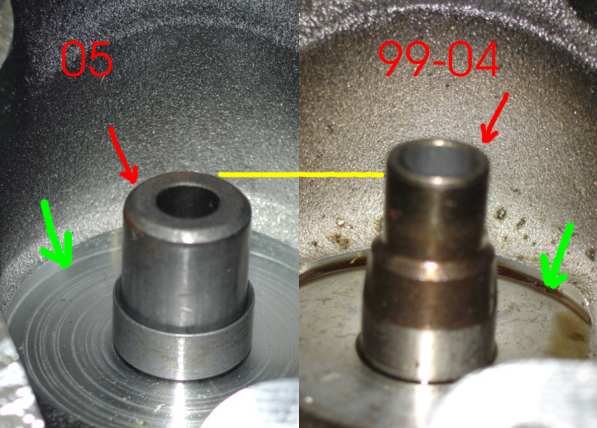

The '05 valve guide is shorter than the earlier guides (Picture 7, yellow line), this allows room for the thicker rubber valve seal to contact with the valve stem. This also allows for an increased valve lift with a performance seal. The wall is also thicker on the '05 guide making it much stronger (red arrow).

Picture 7

I saw it posted somewhere that the valve seal was held in place with a cutout on the head at the spring base. It was also suggested that the Moco quality control on the diameters of the bottom collar might be at fault. As I understand it the bottom collar fit to loosely in the machined groove (Picture 7, green arrows) allowing the bottom collar to move and stress the seal causing it to fail.

But this is what I found ...

After comparing the early heads with '05 heads, they are machined the same and there is no groove for alignment (Picture 7, green arrows). And actually the valve seal, where it seals to the valve guide (Picture 8, red arrow), also locates the bottom collar. The green arrows show that the collar doesn't come anywhere near the machined area, and it is not suppose to either. When the spring is installed, the bottom collar centers it and the spring pressure holds it flat to the head. This in turn securely holds the seal in place on the valve guide. On the earlier style seals, green loctite helps to do this.

Picture 8

The '05 bottom collar serves 3 purposes now.

1) It centers the spring.

2) It stops the steel spring from damaging the aluminum head.

3) It holds the seal onto the valve guide securely.

Valves & Springs

As mentioned earlier, the valve stems are thinner 7mm vs. 8mm. Also where the valve meets the stem (Picture 9, red arrows), on the '05, the radius of the corner is greater which should promote smoother flow.

The thinner stem valves also weights less. The top collars are smaller and weight less also (Picture 9, green arrows). When added up over the 4 valves and collars, the weight savings in the valve train is significant. This reduced the amount of moving mass.

The keepers now use 3 radiused grooves instead of a single stepped slot (Picture 9, yellow arrows). The radiused grooves distribute the force of the spring over a much wider area. The stepped slots put all the pressure on a single edge.

Picture 9

Summary

Summary

The '05 factory heads have more port volume and less port obstruction. The seals are positive locking and have a wider contact area. Less moving mass in the valve train. Stronger valve guides and keepers. Larger radius transition from the valve stem to the valve head. Greater potential for increased RPM's and higher valve lifts using stock parts.